The MOV-10DxxxK Series of 10 mm radial leaded varistor devices protects against overvoltage transients such as lightning, power contact and power induction. The metal oxide varistors offer a choice of varistor voltages from 18 V to 820 V and Vrms voltages from 11 V to 510 V.

Use this to protect against overvoltage transients of any mains connected device (240VAC). See https://en.wikipedia.org/wiki/Varistor.

The devices have a high current handling, high energy absorption capability and fast response times to protect against transient faults up to rated limits.

When used as protection devices, they shunt the current created by the excessive voltage away from sensitive components when triggered.

Also known as a voltage-dependent resistor (VDR).

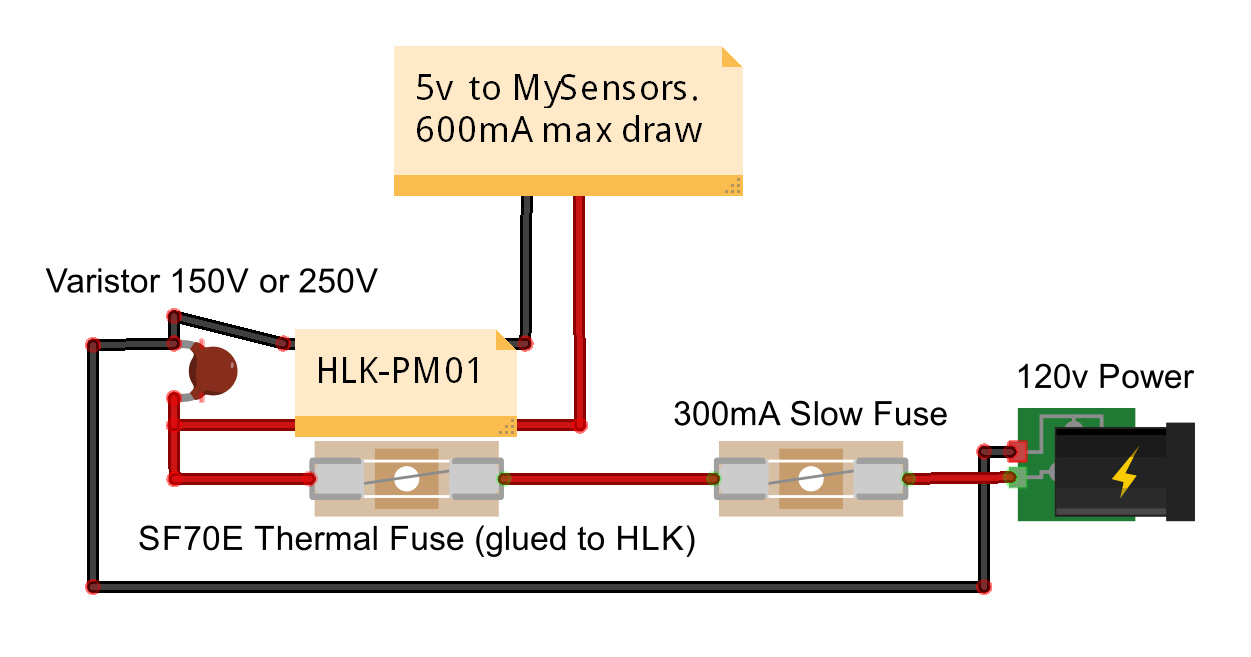

A series connected thermal fuse is one solution to catastrophic MOV failure.

Dimensioning Operating Voltage

For European public AC power networks, IEC 60038 specifies that a line voltage tolerance of ±10% is to apply as from the year 2003. In this selection example we shall assume this tolerance to apply. This means that a maximum required operating voltage of 253 VAC must be taken into account when selecting the varistor (the negative tolerance is of no significance for varistor selection). To achieve the best possible protection level, the varistor types with the maximum continuous RMS voltage just above 253 Vrms must be chosen, i.e. according the Bourns MOV datasheet the voltage 275 Vrms.

However, e.g. for use with a HLK-PM01, a 10D561 is advised. This MOV has a 350Vrms maximum continuous voltage rating.

Datasheet

- Bourns (pdf)

- Ceramate (pdf)

- Littlefuse Application Note 9311 (pdf)

- TDK dimensioning (pdf)

See https://www.electronics-tutorials.ws/resistor/varistor.html.

See https://en.wikipedia.org/wiki/Surge_protector.

See https://forum.mysensors.org/topic/1607/safe-in-wall-ac-to-dc-transformers/2